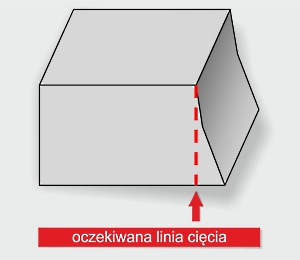

Non-perpendicular cutting, also known as beveling, refers to the lack of perpendicularity of the cut surface.<!–more–> Sometimes, when cutting metal, some operators of band saws fill the arms of the vise to the maximum, thus wanting to speed up the whole process. Unfortunately, very often such action leads to the occurrence of a non-perpendicular cut. However, this is not the only reason.

Primary causes of beveling:

(a) too little tension on the band saw,

(b) too high a feed rate (the rate at which the band saw plunges into the material being cut),

(c) the speed of the band saw is too slow,

(d) poorly selected pitch (too fine a serration in relation to the size of the material to be cut),

(e) hard inclusions in the material or its hardened surface

(f) slides that are too wide apart,

(g) excessively loose or worn wearing parts in the guides (bearings or carbide plates),

(h) dulled band saw (e.g., due to lack of lapping).

It is also worth noting that the likelihood of a non-perpendicular cut increases with the presence of several causes at the same time.

If the cause of a non-perpendicular cut is a malfunction other than dulling of the saw, in practice it is most often the case that a saw that once started beveling will continue to do so – even after the causes of beveling have been removed.

This is because during non-perpendicular cutting, the teeth of the band saw are unevenly blunted on one side.

A beveling band saw, whose serrations are still capable of cutting through material, is suitable only for “non-production” cutting. – that is, wherever surface perpendicularity is not required, and the cutting operation itself precedes other cutting operations occurring in a given production process.

We hope that the above article will help you eliminate the problems of emerging non-perpendicular metal cutting. In case of additional questions or ambiguities, please contact us directly – our highly qualified specialists provide professional assistance at every stage of product use.